AWB Anlagen- und Werkzeugbau GmbH & Co. KG has manufactured components and tools of hardest and heat-resistant materials for more than 25 years, in addition to special tools and customised workshop and tool containers.

With AWB Aviation GmbH, we fulfill all criteria that are required by a supplier for the aerospace industry.

AWB – we produce safety-relevant components of certified quality from materials that are difficult to machine

For more than 25 years, AWB Anlagen- und Werkzeugbau GmbH & Co KG has been producing components and tools made of the hardest and heat-resistant materials as well as special tools and individual workshop and tool containers. Since 2015, when AWB Aviation GmbH was established, we have also been a certified supplier for the aerospace industry.

Special tools for the assembly and revision of turbines as well as special containers as individually manufactured workshop and tool containers form another special field of our portfolio.

“If workshop containers, then from AWB”

Statement from a leading DAX company

Your expert for the construction of special containers and workshop containers

What makes us unbeatable?

We manufacture and deliver at the highest quality level in record time: within 6 weeks*! With us, you can rely on more than a quarter of a century of engineering experience and know-how.

We supply special and workshop containers for medium-sized companies and global market leaders. And precisely to any location on the globe. In addition, there is the AWB all-inclusive service package: from consultation and configuration to logistics and refill. On request, AWB will accompany the entire life cycle of your special container – and that is a very long time …

Get to know the world of AWB special and workshop containers: made for tough use in all places on earth on land and at sea. From specialists for professionals.

Learn more:

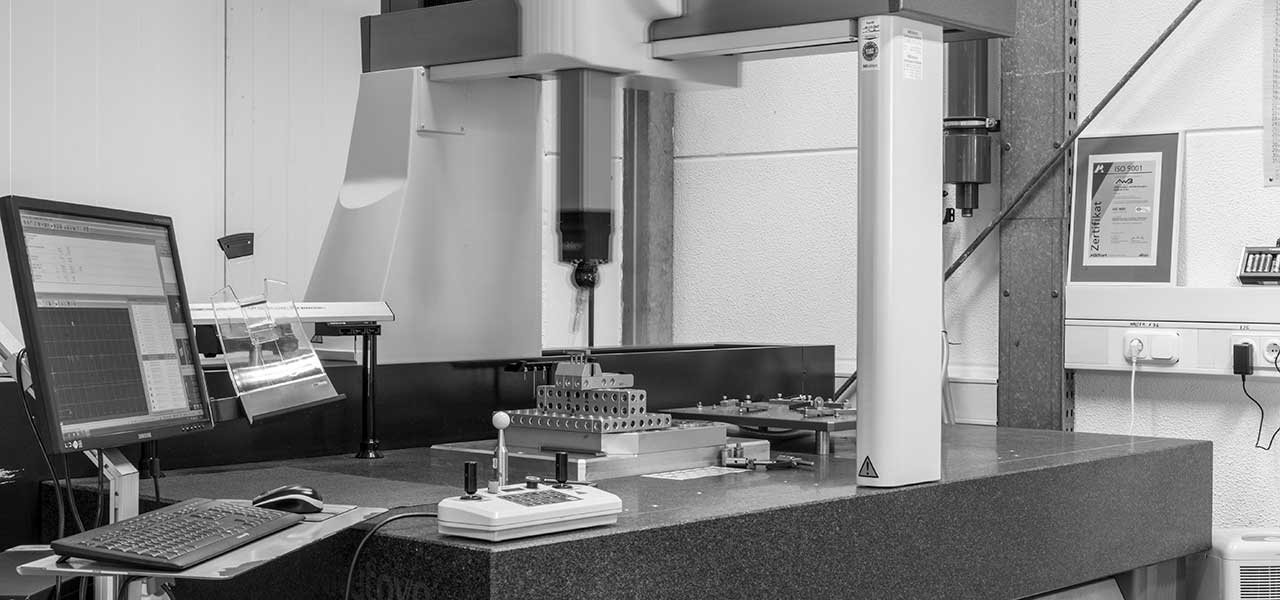

Precision manufacturing of components

AWB produces with an accuracy of up to +/- 2 μm. We achieve this very high accuracy by using a quality assurance process ensured by our highly qualified employees and stringent process control. The entire precision manufacturing process is monitored by an integrated EDP system. This also guarantees traceability of individual parts if required.

We don’t just control quality at the end of each production run, we produce it continuously.

Examples of components with precision manufacturing made by AWB

- Hot gas parts for gas turbines (burners, nozzles etc.)

- Components shrunk into turbines (cooling pipes, nozzles, flanges)

- Parts and assemblies for submarine cables

- Prototypes and assemblies for E-Fly

- Special parts for the hydrogen industry

Examples of materials processed by AWB

- Heat-resistant steels, e.g. Inconel, Hastelloy, Waspaloy

- Saltwater resistant copper / brass alloys

- Acid-resistant stainless steels for petrochemistry and food technology

- Other stainless steels of any quality

- Titanium

Prototype production

From zero to series – with AWB

AWB has many years of experience in pilot series and prototype production as well as in cooperation with R&D departments. This means that our technically highly qualified staff can draw on a solution potential that guarantees optimum and cost-efficient production for you at all times.

Examples of production areas with pilot series and prototypes

- Nozzles and burner parts

- Springs and dampers

- Air intake systems for turbines

- Structures for deep-sea cables

Single part & small batch production

Quality down to the smallest detail

Single part and small batch production is particularly suitable for complex parts and products made of special materials. We produce from 1 to 5000 parts and can even process orders at short notice. We guarantee the highest quality standards here as well. Advantage of AWB: We can easily convert drawings and 3D models into machine programmes.

Manufacture of welded constructions and large components

AWB manufactures welded constructions and large components weighing up to 25 tons. By doing so, AWB uses its knowledge in working with stainless steel and black material to produce high-quality welded constructions and large components for you.

For example, AWB manufactures the following products in the field of welded constructions and large components:

- Bearing blocks for turbine rotors

- Lifting devices for entire turbines or turbine parts

- Motor frames

- Scaffolding and constructions of any kind

AWB GROUP

Chemiestraße 8a

D – 68623 Lampertheim

Phone +49 6206 – 9428 -0

Fax +49 6206 – 9428 -28

info@awb-gmbh.de

If you are in need of a machine list, a list of processable materials, certificates or attestations, please don’t hesitate to send us a short mail!

Michael Appelt

Turbines / Energy Technology /

Welded Constructions

Phone +49 6206 – 9428 -12