What makes us special

Technology with Potential

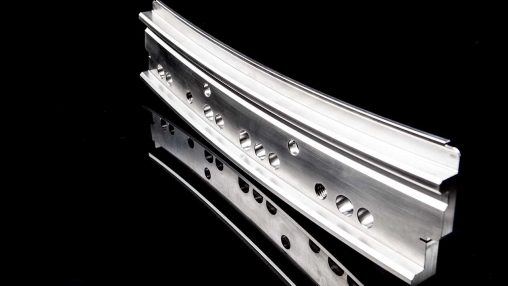

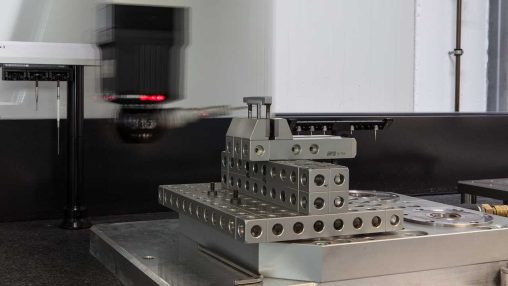

State-of-the-art 5-axis milling machines work with an accuracy rate of up to 2 thousandths of a mm.

Inconel®, Hastelloy® and Nimonic®

We manufacture safety-relevant components of high-performance turbines from the hardest and most heat-resistant materials.

Needless to say, we also process titanium and aluminum, as well as other aviation-approved materials for aircraft.

EN 9100 – Consistently Realized!

We work on state-of-the-art machines in a clean environment and with highly-qualified employees.

Time for Quality

Quality is important to us. Therefore, our employees have time to check each product individually.

Single Pieces, Small Series, Serial Production

The AWB Group is well equipped for prototyping, the rapid delivery of spare parts and serial production.

We Take Our Responsibility Seriously!

The quality tests performed in our measuring room always exceed your specifications.

Your Tools, Available Worldwide

We offer you customized solutions so that you can use your workshops worldwide.

Special Tools for Special Applications

We manufacture special tools and platforms for large machine assembly, as this and the revision work requires highly-individualized tools. We manufacture them!

The Dream of Flying…

You get onto a plane and feel safe. This is because all the companies involved in the construction and maintenance of your aircraft are carefully selected, and they all provide the highest level of service in addition to satisfying the most stringent regulations. We, AWB Aviation GmbH, are such a certified company:

We Think Things Through Thoroughly – Which is Why We Do a Good Job!

Whether we deliver a fully-equipped service container or special tools for the maintenance of a gas turbine – we are proud of our employees! They always do their best, from the planning stages and right up to the implementation, thereby greatly simplifying the lives of many others.

Secure Energy Supply – Around the Clock…

A gas turbine – 50 meters long, 50 tons in weight, consisting of more than 30,000 parts, 2,500 degrees Celsius, an output of 50,000 HP… We have been manufacturing components that can withstand unimaginable forces under the highest temperatures for more than 20 years. With great attention to detail, highest precision and a quality standard that is second to none!

Shining with innovations!

In the course of the past 25 years, our company has grown continuously and healthily. Looking toward the future has always been our core focus. We are continuously – and successfully – looking for solutions to our customers’ problems and requirements. We expand our deployed machinery, adapt our control and testing systems and always think one step ahead. This creates a long-term and valuable relationship with our customers, which also offers invaluable benefits for both sides.

Reliability and Tradition

Traditional values such as our much-praised reliability as well as the invaluable capital provided by our employees’ experience play a major role in our company. Even though every single product has to pass through sophisticated testing processes, it is the motivation of our employees to produce the best products that is the most important factor in all processes. Above-average training, a long service life and a functioning structure place us in a position that enables us to x meet all quality criteria for the manufacture of safety-relevant precision components at all times.

Reaching You Faster!

The delivery time is a decisive criterion in the sourcing of spare parts. We have created a system of processes that allows us to react very flexibly to your production-related needs.

Download PDF presentation

on the topic of workshop container production

Download Brochures on the Topics: